Shunta SuzukiSORA Sous Chef

Recommend Tour02

Shunta SuzukiSORA Sous Chef

Recommend Tour02

Traditional craftsmanship is alive and well in Hokuriku.Among these, Echizen City is particularly unique.Looking back on history, this area was the center of Japan's economy and culture during the Yamato period (710-794) and became the national capital of Echizen during the Nara period (710-784) and thereafter, then Culture and crafts have been nurtured and deeply rooted in this background.

This time, I have invited my colleagues who work together at Takigahara Farm to join me on a trip to introduce the charms of Echizen City's craft culture.This time, Chef Shunta Suzuki of Hotel Craft&Stay, which is located in an old private house.He is a sous chef at the one-star restaurant “SORA” in Paris, and has returned to Japan for a time to put his skills to use while awaiting convergence at Takigahara due to Corona.

In order to have visitors experience Echizen City's crafts from a chef's perspective, we first went to Okamoto Shrine and Otaki Shrine, a sacred place for washi paper.

As we proceeded deeper into the area, savoring the atmosphere of the Imadate district, where washi paper studios are clustered, we came upon a shrine.

This shrine is dedicated to “Kawakamigozen,” the goddess of paper.

Once inside the shrine grounds, the environment is filled with the tranquility unique to shrines.

We will share with Shunta the knowledge of why this area has become one of the leading producers of washi in Japan, which we will learn as we visit the shrine.The god who brought washi making to this area must be a female deity.As is the case with Kikurihime in Hakusan, Hokuriku is good for having many female deities.

After going up the stairs and past the temple gate, you will see a roof shaped like nothing you have ever seen before.And if you look closely, you will see that the entire building is carved at a tremendous level.Shunta was at a loss for words at the presence of the decorations, saying, “Aesthetics has nothing to do with new or old”.

Still, no matter when I come here, the atmosphere here is always different from others.

The next stop was Osada Paper Mills, a washi (Japanese paper) workshop that specializes mainly in shoji paper.

We were greeted by Kazuya Osada, the fourth president of the company.

As he showed us around his workshop, he carefully explained to Shunta about the process and particulars of washi papermaking.Osada Paper Mills is a workshop that has been making washi paper for over 100 years since its establishment, specializing in fusuma paper (sliding door paper).Mr. Osada has brushed up the “Hiryu” technique produced by the second generation and is expanding the possibilities of washi by applying it not only to sliding doors but also to various other products.

It has the feel of an art piece rather than a traditional craft.

What impressed Shunta the most in Osada's talk was that “we are trying to push the idea of being as natural, healthy, and sustainable as possible,” said Shunta.It's great to see a bold, future-oriented idea, such as the crowdfunding challenge to make completely additive-free paper in 2019!

The Papyrus Museum and the Udatsu Crafts Museum are located in the center of the production area, in an area called the Washi no Sato Dori, where washi related facilities are gathered.Both facilities offer hands-on washi-making experience, but the Papyrus storeis an unforgettable place for those seeking washi products, with a wide range of washi products all under one roof.

Shunta was given a hands-on papermaking experience at the Udatsu Crafts Museum.

As the name suggests, the building has a powerful appearance with a magnificent udatsu standing on top of it.

The building, a relocated and restored paper-making house from the mid-Edo period, has been carefully renovated to provide a comfortable environment.The overall impression is clean, and the environment is conducive to an authentic papermaking experience.With the help of the instructor, Shunta finally had a chance to try his hand at papermaking.After several failed attempts, it was a great feeling to finally make a beautiful paper.Shunta said he was able to do it better when he felt the rhythm in his body and let it soak in, rather than trying to understand it in his head.The paper you make will be sent to you at a later date.

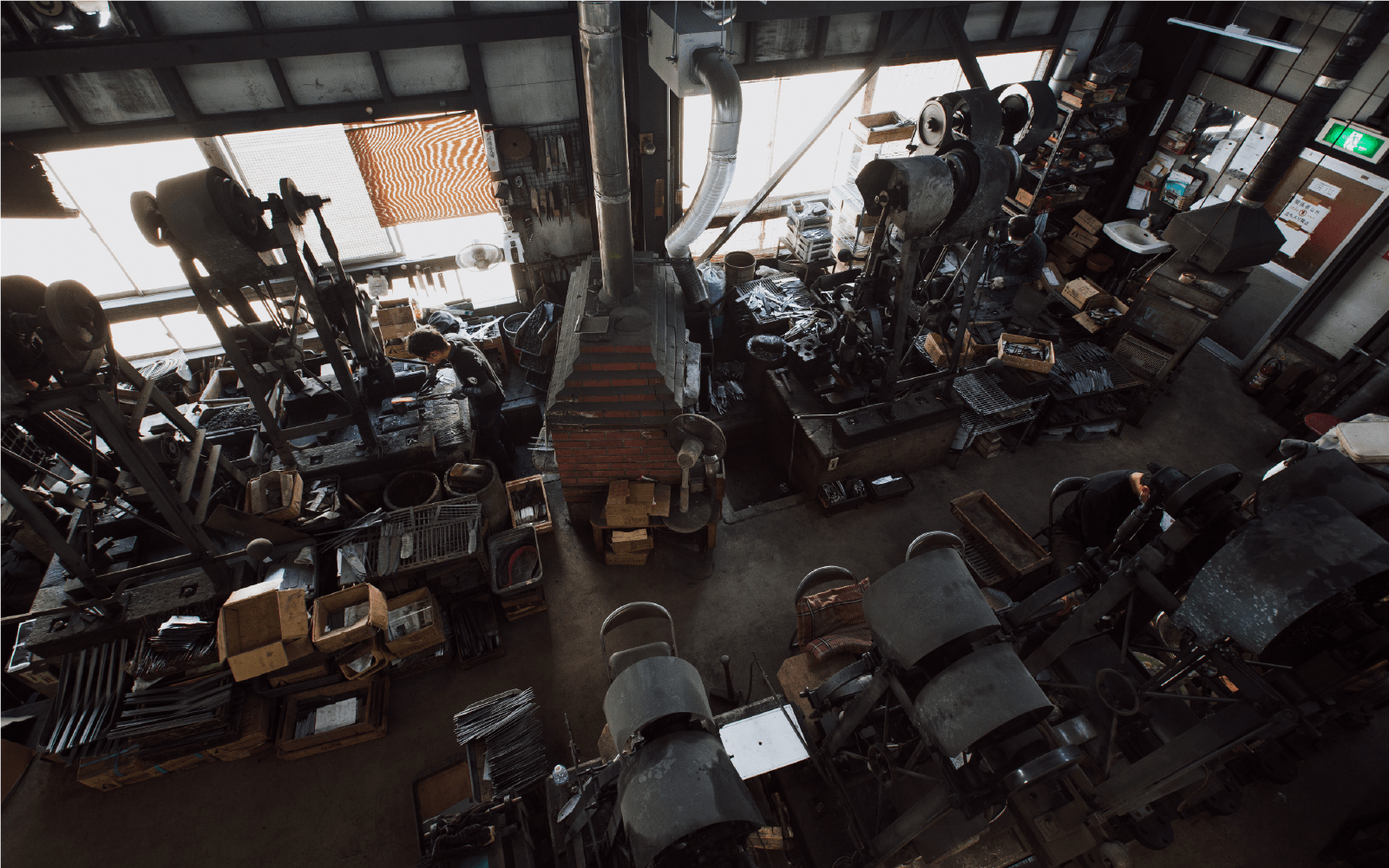

Next, head for the area where Echizen Uchihamono (Echizen hammered blades) workshops are concentrated.

Echizen hammered blades are said to have originated around 1300 when Kyoto swordsmith Chiyozuru Kuniyasu came to present-day Echizen City in search of a suitable location for sword making, and began making sickles for the farmers in the area.Echizen hammered blades are characterized by the ancient fire-making forging technique and hand sharpening.The “Nimai hiroge” method, in which two pieces of steel are piled up and hammered together, and the “Mawashi haganeduke” method, in which a good blade can be made thin, are particularly well-known.

While other regions have shifted to mass production, we have continued to focus on handmade work and our artisans have worked hand in hand to improve their craft. As a result, we have received inquiries from chefs and connoisseurs around the world, and now have a growing market.

This time, we visited “Ryusen Hamono,” which was one of the first Echizen Uchihamono makers to commercialize stainless steel products and pioneered the field of kitchen knife making for home use.

Speaking of Ryusen Hamono, the "Ryusen ring" appears when materials of different hardness are stacked and sharpened.As he showed us around the workshop, he told us how hammered blades are produced and the characteristics of Echizen hammered blades.

As a chef, fermentation culture, especially sake, is an important subject as a way to learn about the local climate.This time, we visited one of Echizen's representative sake breweries, “Katayama Shuzo,” to talk with them.

In fact, 2020 was a major turning point in the sake environment in Fukui.A new type of sake rice called “Sakahomare,” whose development began in 2010 with the goal of producing the best daiginjo as well, has been harvested, and brewing of Sakahomare sake has begun simultaneously at sake breweries throughout Fukui Prefecture, and the timing is finally right for the release of new sake.Katayama Shuzo also released “Tsukigasa” using new rice.

Katayama Shuzo is a sake brewery with a long history dating back to the 1700s.

The taste of “Tsukigasa” was neat and free of clutter, as is typical of daiginjo.

Fukui is known for soba noodles.There are 22 strains of native buckwheat in Fukui Prefecture, but the Masuda Soba Flour Mill only produces stone-ground buckwheat flour from native varieties of buckwheat grown in Fukui and neighboring areas, including its own cultivation.The charm of Echizen soba lies in the primitive flavor of the unbred native species.If it is ground with a stone mill over a long period of time, it is bound to taste good.

Mr. Masuda shared buckwheat flour with us to be used for the evening meal.

This concludes the first day's coverage.

From here, we will gather with the washi artisans at the “Kioku no ie,” a gallery run by Osada Paper Mills that offers overnight accommodations, for Shunta's dinner party. Mr.Hideaki Taki, the seventh generation of Taki Paper Mills, and Mr.Izumi Osada, the fifth generation of Osada Paper Mills, joined us.

We use a Santoku borrowed from Ryusen Hamono.

Santoku is a very easy-to-use knife for home use.As a professional chef, Shunta does not often use Santoku knives, but he has recently been paying renewed attention to their ease of use, and this time, as the participants watched, he used Ryusen Knives's Santoku to quickly and beautifully handle the fish.That is no wonder, as he was trained at the famous Japanese restaurant “Ryugin”

We talk until late, exchanging delicious food and Katayama Sake Brewery's Tsukigasa.

They are the next generation of a workshop that has a long history with each other.Craftsmen are really workaholics.We talked about work until late into the night.

The second day started with Taki Paper Mills, which was established in 1875 and mainly produces large sheets of paper.Mr. Taki, who started work early in the morning and had already finished warming up, demonstrated his specialty technique.Shunta does this for us, and it is clear that even the simple task of sprinkling water requires the skill of a craftsman.

Yesterday, Ms. Osada and Mr. Taki's workshop each specialize in large-size paper such as fusuma (sliding door) paper.The only environment where this size is routinely made is in Echizen.The collaboration with the Dutch contemporary artist “Theo Jansen” that began in 2018 was also made possible by this large format technology.The environment is now attracting attention from all over the world.

Shunta is pleased to receive a scrap of paper from Mr.Taki. Washi has a high affinity in the culinary environment, including menus.

Next, we will head to the Takefu Knife Village Cooperative, which is also the site of the 2020 Millennium Future Crafts Festival.During our two-day tour of the entire Echizen City area, we realized that the entire Echizen City area is dotted with workshops engaged in crafts, just like a village.The distance is just right for a drive around.

Takefu Knife Village is a facility that brings together in one place the manufacturing and sales environment for Echizen hammered knives, which are jointly operated by 12 workshops.More than 40 artisans work there, 17 of whom are traditional craftsmen.Furthermore, the age range is wide, with the oldest being 80 years old and the youngest 18 years old.This is a rare facility that literally has a sustainable business environment.

Mr.Totani, a traditional craftsman, gave us a tour of the facility, which opened a new wing this year, bringing it even closer to hammered blades.In the new building, the store function has been enhanced to allow visitors to see and touch products from various companies all in one place.Overall, the design does a good job and gives the facility the impression of updated craftsmanship.The gallery displays knives for a variety of uses and is very impressive.

The main building is designed to overlook the work area, giving visitors a clear view of the craftsmen's hands.

Shunta purchased a small Santoku, an original Knife Village product.

It is a lightweight and compact knife that makes you want to cook anytime.

Back in Takigahara, I immediately started cooking with a knife.Together with my colleague Reina, we had a meal with cutlery from Ryusen Knives.

Yoichi Uchiki / Botanically Photography and Planning

He has 20 years of experience in marketing positions in foreign companies and pharmaceutical trading companies.