Many people think of forged kitchen knives when they think of "Echizen Uchihamono", a traditional craft of Echizen City. However, what was made before knives was actually a sickle for agricultural work called the "Echizen sickle".

Sickles may not be so familiar today, but they are actually one of the most useful tools in a wide range of situations, such as weed cutting, rice harvesting and vegetable gardening.

Let's take a closer look at the Echizen sickle, which is indispensable for such agricultural work.

Echizen sickles made with the skills of a swordsmith.

The production of Echizen sickles began in the Kamakura period(1185–1333). It is said to have originated when the Kyoto swordsmith Chiyozuru Kuniyasu stayed in Echizen in search of water to forge his famous swords, and began to make sickles as well as swords.

In the Edo period(1603 - 1868), each lord strengthened the protection and fostering of agriculture and forestry and the total area of fields expanded. This led to the mass production of agricultural implements and the Echizen sickle was transferred to various regions.

The sickle peddlers played an important role in its spread.

Penetrated throughout the country by Lacquer scraper.

Echizen sickles were sold by merchants who lived in Fuchu Takefu, which is now Echizen City. Many sickle peddlers were originally "lacquer-pickers" who collected the juice that flowed from the lacquer, and farmers from the mountain villages of Kawada (in Sabae City), where Echizen lacquerware is produced, Ikeda Town and the present-day Imadate area worked as lacquer-pickers all over the country.

The Echizen sickle was always taken along when the lacquer-pickers went out to work. The advanced technology developed in the production of swords boasts outstanding sharpness and robustness. Lacquer shovelers used these sickles for their work and, at the same time, when the shoveling work was closed due to rainy weather, they sold the Echizen sickles they brought with them to people in nearby mountain villages, bringing back orders for sickles that suited their local characteristics.

In the Meiji era (1868-1912), inexpensive Chinese lacquer solution began to be imported, and when Japanese lacquer became unsaleable, more and more lacquer shovelers changed their trade to peddling sickles. The production of sickles has also decreased, but even so, the Echizen hammered cutlery production area has followed a stable path, with the majority of the nation's sickle production being produced in Echizen until the early Showa period.(1926–1989)

Echizen sickles continue to be made using traditional methods.

After the war, the advent of a period of rapid economic growth led to the rapid mechanisation of agriculture, and the production of Echizen hammered blades also shifted from sickles to kitchen knives and knives.

Today, the number of workshops making Echizen sickles has decreased completely, but there are still some workshops in Echizen City that continue to make them using a technique that has been handed down from generation to generation.

They are "Kato Uchihamono Manufacturing" which has workshops in Takefu Knife Village and Echizen city centre.

3For three generations, the company has been producing forged kitchen knives, but the process of making saw blades for harvesting rice and other agricultural work is a special technique that has only been inherited by Kato Uchihamono factory in all of Japan.

The saw sickle, as the name suggests, has a jagged blade. Many sickles, such as those made overseas, are made by die-cutting steel by machine, but at Kato Uchihamono factory, the eyes are cut by hand, one by one, using a method known as "Mekiri".

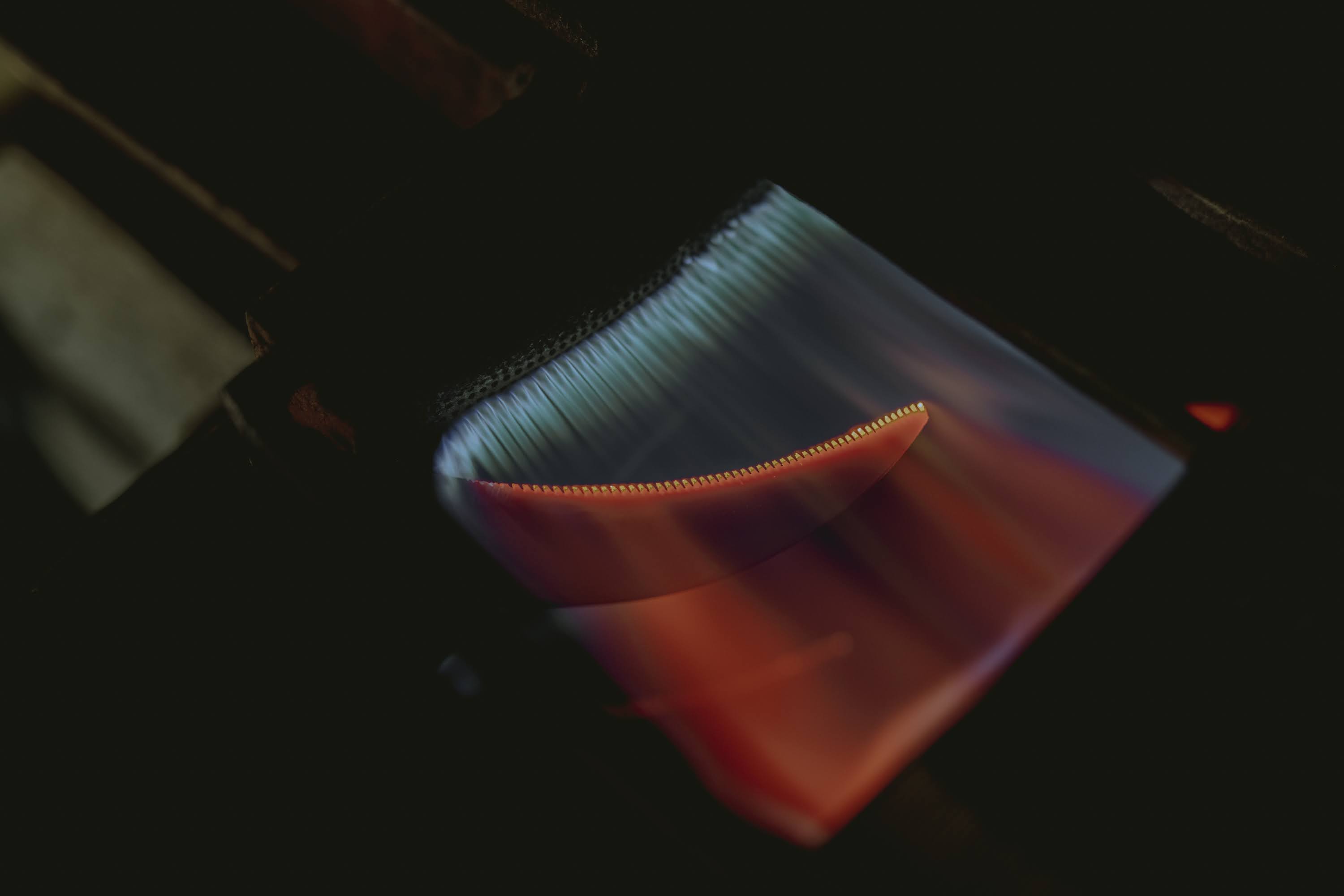

▲The steel is pressed against the grooves of the machine and then grained.

The jagged parts are then sharpened. The process of carefully sharpening each blade with a file is precise and very time-consuming.

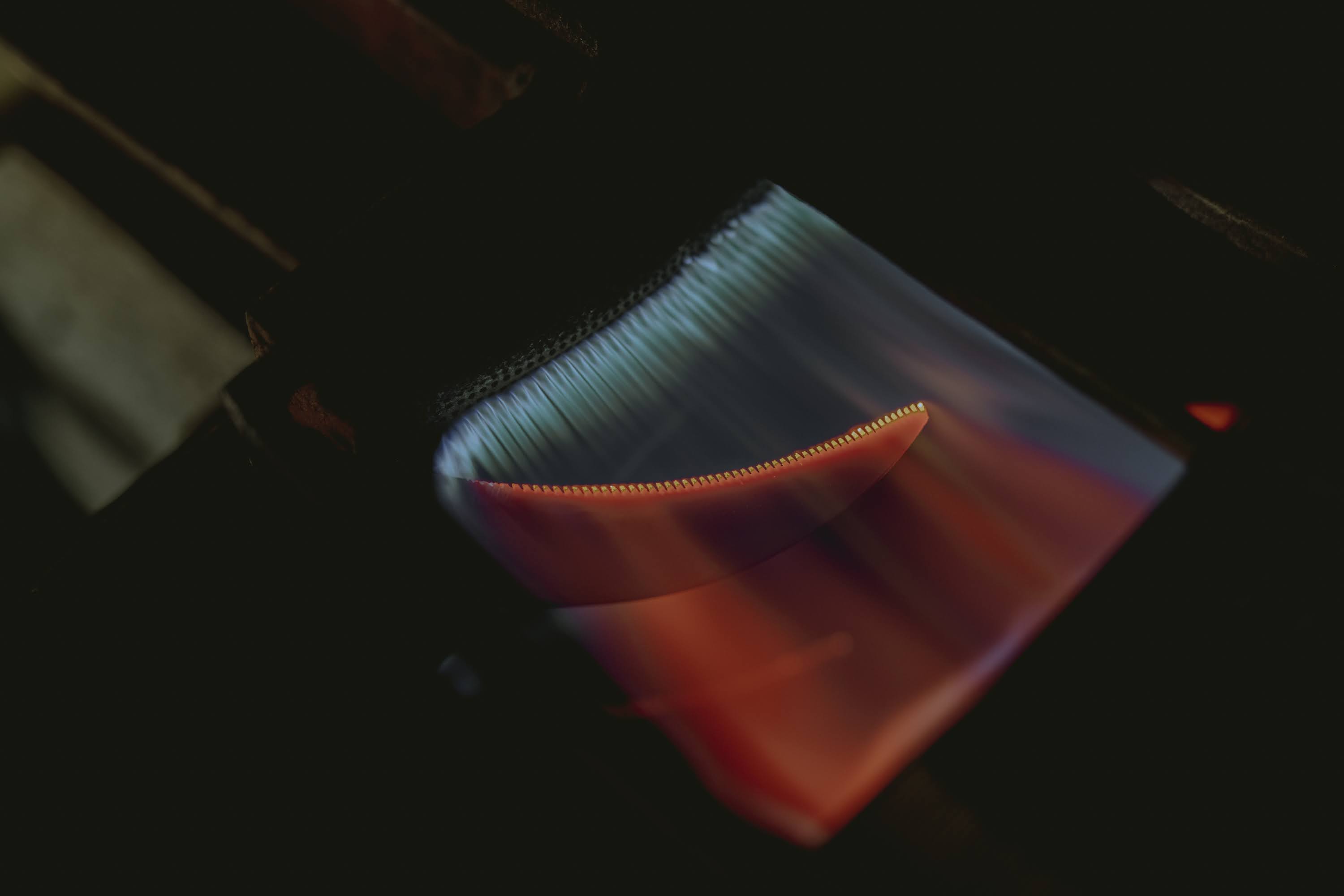

▲The sound of shuffling and filing echoes through the workshop.

The grained sickle is heated to a high temperature over a fire of around 800℃ and cooled at once with water to produce hardness. Sickles made through this process are strong despite their thin blades.

Saw sickles are usually replaced every year. Some saw blades become worn out before the end of the harvest season if they are overused every day, but Kato Uchihamono factory's saw scythes never lose their sharpness until the end of the year's harvest.

"When we do the grading by hand, the lengths of the blades are slightly different, some longer and some shorter. So, as you use it, the long blades wear off, but the short blades are still sharp, so it keeps its sharpness for a long time."

Mr Kato, who continues to make Echizen sickles at the Kato Uchihamono Factory, told us.

▲Mr. Kato, his been making Echizen sickles for more than 20 years. His gentle smile, far removed from the image of a stubborn craftsman, is a charming feature.

There are other advantages to handcrafting besides sharpness.

Special sickles can also be made to suit the user's needs.

In addition to rice harvesting, there are various other types of sickles, such as "the weeding sickle", which is particular about the angle at which it enters the soil when weeding, and "the asparagus sickle", whose handle length also indicates when it is time to harvest.However, "Rakkyo sickles" and"left-handed sickles", in which the direction of the blade is in the opposite direction to normal, can only be made by manual cutting.

"Sometimes I wonder why I keep doing this hard work (laughs).But I still like the sickles that are made by hand."

laughs Kato.

No matter how mechanised they have become, sickles are still useful in small fields and home gardens where farm machinery cannot enter. Many people find that once they use it, they can't put it down because of its ease of use, including its good balance that fits comfortably in their hands and its sharpness that allows them to mow without stress.

The Echizen sickles, lovingly made using techniques handed down over many years, will continue to be a reliable partner for farmers in fields all over the country.

<References>

The Sound of the Hammer: Uchihamono from Echizen Takefu (Kaizo Saito, The Sound of the Hammer: Uchihamono from Echizen Takefu Publication Society).

Text / Ai Ishihara